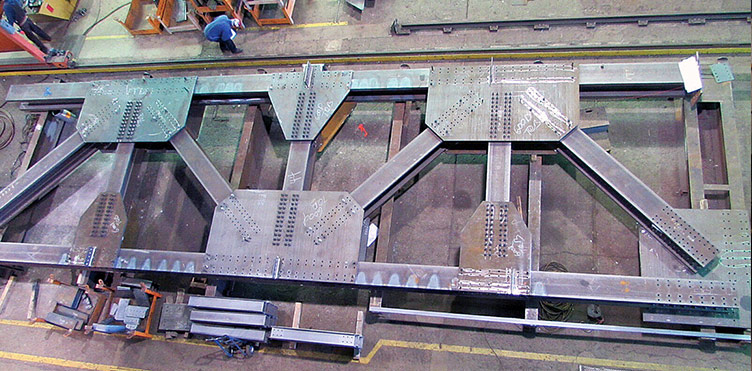

Just like other advancing industries, the proliferation of new technology shapes the efficiency of construction projects. DfMA elements can be created using the same materials and design codes and standards as conventionally built projects, or new materials and design standards may be developed.

In some cases, up to 90 percent of individual DfMA elements can be completed on the factory floor. This practice produces a greener, faster and smarter outcome with:

DfMA can produce a quality product in up to half the time of conventional on-site construction.

Building with DfMA elements avoids unpredictable weather and site conditions causing delays. Off-site construction allows tasks to be conducted simultaneously instead of multiple trades competing for space.

DfMA buildings are generally stronger, as each DfMA element is engineered to independently withstand the rigours of transportation and placement.

Factory construction also enhances control and consistency as efficiencies are maximized while avoiding on-site risks like workmanship, site congestion and bad weather.

Removing up to 80 percent of construction activity from the site reduces disruption and traffic while improving overall safety and security. Factory production is more predictable and eliminates risk factors such as:

This results in less errors and general hazard avoidance.

The need for environmentally friendly building practices is on the rise, alongside the push for more sustainable building materials. Off-site construction methods like Design for Manufacture and Assembly (DfMA) play a crucial role in addressing these needs.

According to the Waste Resource Action Program, producing a DfMA modular-based building uses only 33 percent of the energy required for a conventionally built project. This significant energy reduction is achieved by leveraging a controlled manufacturing environment, which allows for greater precision and efficiency.

Moreover, DfMA significantly reduces material waste, noise, dust and societal disruption compared to traditional construction methods. The controlled environment of off-site construction minimizes errors and excess material usage, leading to less waste.

Additionally, the shorter construction timelines and reduced on-site activity decrease the environmental impact, contributing to overall sustainability. By adopting DfMA, the construction industry can move towards greener, more efficient building practices that benefit both the environment and society.

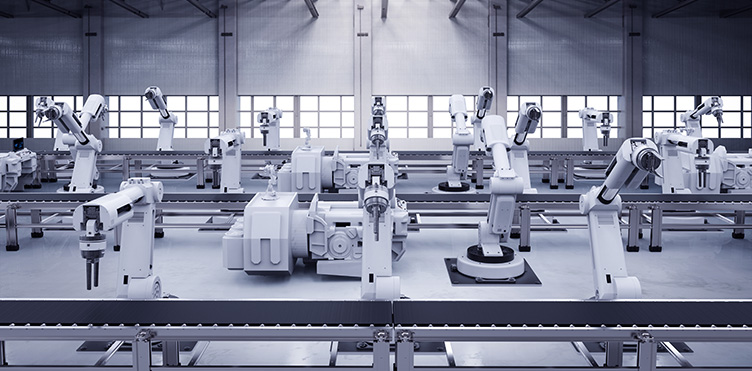

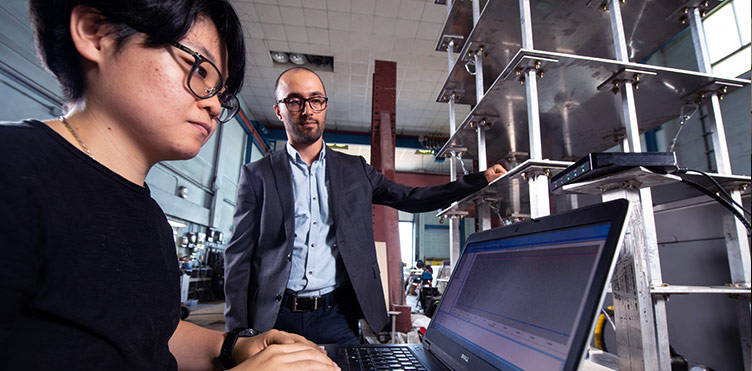

From advanced robotics and automation to building information modelling (BIM), off-site construction is primed for technological gains.

Using BIM means that an accurate virtual model with precise geometry can be constructed to perform a number of processes like:

Off-site can also integrate technologies into the end product for a ‘smarter’ built environment.

DfMA elements are designed for the logistics and transportation required on most project sites.

DfMA elements fit containers for marine shipping, rail cars and truck trailers, allowing manufacturing and shipping from distant locations.